ZMC-CHSB-B1

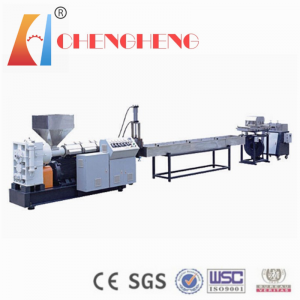

Double stage recycling machine the machine is an equipment to produce plastic glumes by extruding, cooling and cutting particles of polyethylene (plastic film, beverage bottle, lining bag, etc.) or polypropylene (old woven bag, packing bag, tie rope, non-woven fabric, etc.).

- Description

Description

Double stage recycling machine

the machine is an equipment to produce plastic glumes by extruding, cooling and cutting particles of polyethylene (plastic film, beverage bottle, lining bag, etc.) or polypropylene (old woven bag, packing bag, tie rope, non-woven fabric, etc.). The production of spikelets is widely used and is the preferred model for waste plastics recycling industry.

Characteristics:

This equipment is matched with the crushing machine cutting machine. The broken and cleaned plastic, without air drying, can be directly put into the extrusion granulation, the process is simple, the process is advanced, and it is suitable for the different waste plastics using the electric network (which can choose the hydraulic net changing device). The heater of automatic temperature control and national energy saving patent is less electricity, no pollution, and high automation.

Parameters:

| 型号model | ZMC-CHSB-130/110 | ZMC-CHSB-150/130 | ZMC-CHSB-180/150 | ZMC-CHSB-210/180 |

| 主螺杆直径(mm)main screw diameter (mm) | 130 | 150 | 180 | 210 |

| 主机功率(kw)main

Machine power (kw) |

22-30 | 30-45 | 37-55 | 55-110 |

| 主机螺杆转速Main engine screw speed | 55-60 | 50-55 | 45-50 | 40-45 |

| 副机螺杆直径mm Auxiliary machine screw diameter | 110 | 130 | 150 | 180 |

| 副电机功率(kw)Secondary motor power (kw) | 7.5-11 | 11-15 | 15-18.5 | 22-30 |

| 换网电机功率screen change motor power | 1.5 | 2.2 | 3 | 3 |

| 配套切粒机功率The power of the matching granulator | 1.1 | 1.5 | 2.2 | 3 |

| 生产能力(kg/h)Production capacity (kg/h) | 100-150 | 1 50-200 | 200-300 | 300-500

|